Quickly find

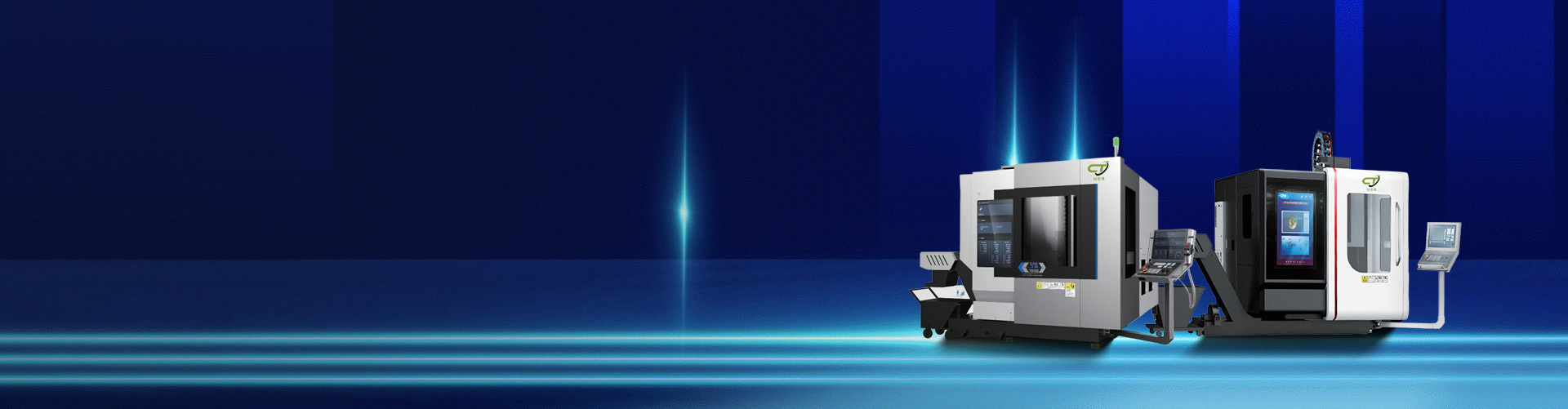

VMC-180 Five-Axis CNC Machining Center

5-axis Vertical CNC Machining Center

Boring and milling machine

CNC Slant Lathe

1. Integrated casting bed base with high rigidity.

2. A2-5 spindle structure. Spindle adopts domestically produced high-quality angular contact bearings (front 3 and rear 2 paired configuration), ensuring high speed, high precision, low noise, and high rigidity..

3. 8-station electric tool magazine..

4. 35⁰ inclined bed..

CNC Slant Lathe

Integral bed seat, fully enclosed protective cover (optional semi-enclosed type).

High efficiency, high precision, good reliability.

Turning inner and outer cylindrical surface, cylindrical surface, circular arc surface and other rotary and end surface, thread.

Equipped with four stations automatic rotation selection tool holder, multi-station continuous processing.